· Hersh Kshetry · Case Studies · 2 min read

High-Performance MBR Retrofit – Urban Sewage Reuse Upgrade

Upgraded a municipal sewage treatment facility from conventional activated sludge to a state-of-the-art membrane bioreactor (MBR) system, increasing capacity from ~3.8 MLD to 7.5 MLD within the same footprint

Overview

Upgraded a municipal sewage treatment facility from conventional activated sludge to a state-of-the-art membrane bioreactor (MBR) system, increasing capacity from ~3.8 MLD to 7.5 MLD within the same footprint. This project, serving a large residential township, now recycles wastewater into high-quality reclaimed water for non-potable uses like irrigation and toilet flushing. Three underutilized concrete treatment trains were retrofitted with immersed ultrafiltration membranes, achieving a ~2.6× capacity boost without new civil construction.

Technical & Logistical Insights

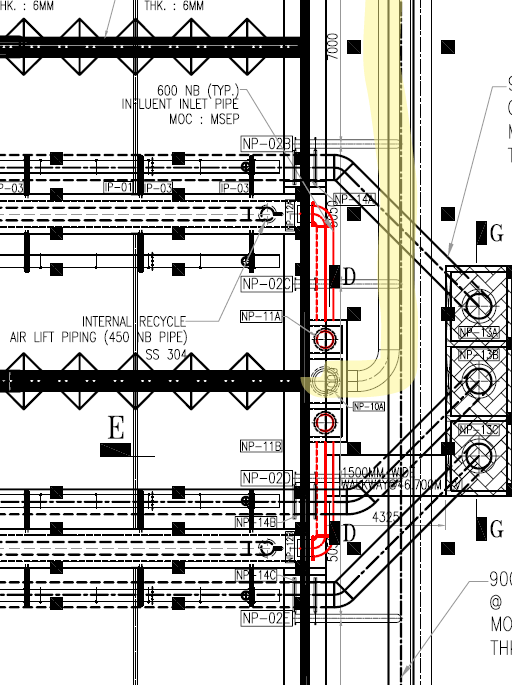

The retrofit leveraged MBR technology advantages – maintaining >8,000 mg/L biomass concentration to enable long solids retention times, which drastically improves effluent quality while saving space. High-strength Teflon membrane modules were selected for their durability and low-fouling operation; the system was designed for a conservative flux (~15 LMH) to minimize cleaning frequency.

Puran Water’s team also integrated energy-efficient blowers and anoxic zones to enhance nutrient removal, ensuring the plant meets stringent reuse standards (achieving effluent BOD ~5 mg/L and TSS ~0 mg/L in routine lab tests). The upgraded plant includes modern automation with remote monitoring and AI-driven analytics to assist operators – optimizing aeration, membrane cleaning schedules, and overall performance. Notably, this project introduced innovative remote operations tools in 2021, allowing experts to support local staff and proactively troubleshoot issues from afar.

Puran Water’s Role

Puran Water led the process re-engineering and implementation for this retrofit. The team developed the basic engineering package and control philosophy for the MBR system, converting existing basins into an integrated nitrification-denitrification MBR scheme. Puran Water coordinated closely with civil and electrical teams to fit new screens, diffusers, and membrane tanks into the old plant layout, solving logistical challenges of construction while the remaining train stayed operational.

Puran Water also programmed the PLC/HMI automation and trained the operating staff. The team’s leadership ensured a smooth transition to the new technology – the plant was commissioned on schedule in 2021 and now consistently produces reclaimed water surpassing regulatory quality requirements, enabling the township to safely reuse millions of liters of water per day.